Femto Laser Machine Services

The significance of femtosecond laser machining services is unparalleled, especially in industries requiring micro components and precise cutting.

Femtosecond laser cutting technology employs ultrafast pulses to deliver precise laser cutting, drilling, and marking with minimal heat effect.

Femtosecond laser processing ensures the highest level of precision, making it the go-to solution for businesses aiming for perfection in miniature.

If you’re looking for a reputable femtosecond laser machining company in the United States, Laserod has decades of professional experience to offer you the best femtosecond laser micromachining services.

Understanding Femtosecond Laser Technology

These femtosecond laser pulses — each lasting only a quadrillionth of a second — emit a concentrated burst of energy that interacts with the surface of the material being processed.

The key to the high precision of femtosecond laser machining is how these laser pulses minimize the heat-affected zone (HAZ).

In conventional laser machining, the heat produced can lead to unwanted changes or damage to the material. However, femto lasers operate differently. The duration of the laser pulse is so short that the heat doesn’t have time to spread to the surrounding material, thereby minimizing the HAZ.

This attribute allows for ultra-precise machining, even on delicate or heat-sensitive materials, marking the superiority of femtosecond laser machining services.

Applications of Femto Laser Micromachining

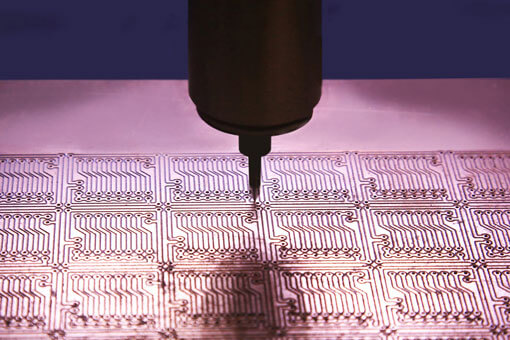

Microelectronics

Femtosecond laser technology offers a non-contact approach to micromachining, making it ideal for working with delicate circuitry and electronics.

Medical device production & biotech

For example, in the field of ophthalmology, femtosecond laser technology provides a cutting-edge solution for cataract surgery.

A femtosecond cataract laser machine’s precision and minimal tissue damage ensure a safer and more accurate procedure, improving patient outcomes.

Aerospace & Defense

The precision of femto lasers allows for complex designs to be machined with high accuracy, making it an essential technology for these demanding applications.

Fiber optics & telecommunications

Femto lasers can produce intricate designs and micrometer-sized features with unmatched accuracy, making them an ideal choice for producing advanced fiber optic technologies.

Benefits of Femtosecond Laser Processing

The advantages of femtosecond laser machining are compelling, whether it’s the precision, detail, speed, or minimal thermal impact.

High precision & detail

This level of precision is unmatched by other laser technologies, making femtosecond laser machining the go-to choice for industries where accuracy is essential.

Speed & efficiency

This allows for increased production efficiency and reduced lead time, making it a cost-effective solution for businesses.

Minimal heat effect & non-contact processing

The non-contact nature of femto laser machining also ensures minimal damage to surrounding materials, making it an ideal method for working with delicate or heat-sensitive materials.

Enhanced quality & versatility

From metals to plastics and even glass, femto lasers can handle a wide range of materials with precision and accuracy.

Laserod’s Expertise in the Femtosecond Laser Industry

As a reputable femtosecond laser machining company in the US, we have honed our expertise in utilizing this cutting-edge technology to its full potential.

Vast portfolio of femtosecond laser projects

From aerospace and defense to research institutions and medical device companies, we have the experience and knowledge to handle any project with precision and accuracy.

Customized solutions for unique applications

That’s why our team works closely with each client to develop customized solutions tailored to their specific needs and requirements.

Exceptional customer service

From initial consultation to post-project support, our team is dedicated to ensuring client satisfaction at every step of the process.

State-of-the-art femtosecond laser systems

This allows us to produce high-quality results with unmatched precision and detail.

FAQs: Your Femtosecond Laser Processing Questions Answered

What is the difference between femtosecond laser processing and other laser technologies?

What kind of materials can be processed using femtosecond lasers?

Contact us to discuss your specific needs, and our team will provide customized solutions for your project.

How much does a femtosecond laser service cost?

We can also provide a free quote to help you estimate the cost of your project.

Get Precision Femtosecond Laser Machining Services with Laserod

With a commitment to quality, precision, and customer satisfaction, we have established ourselves as a leading provider of femtosecond laser machining solutions in the US.

Contact us today at 310-328-5869 or email us at sales@laserod.com to learn more. Unlock the full potential of femtosecond laser processing with Laserod!