Laser Resistor Trimming Services

Overview

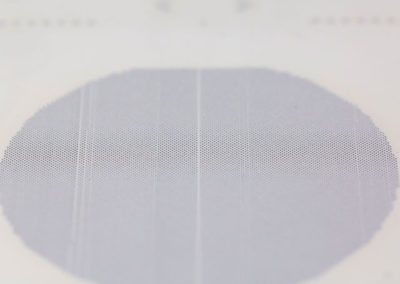

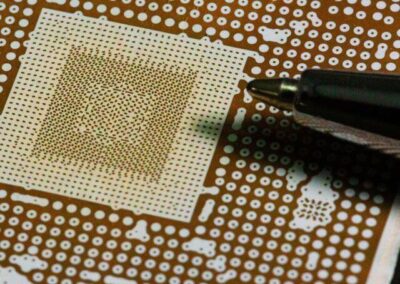

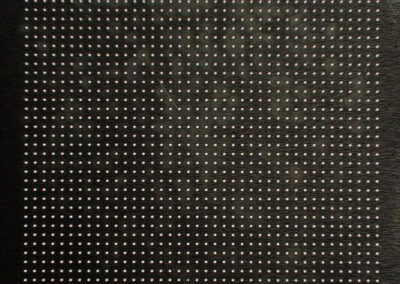

Laser trimming of passive or active components, typically resistors, has become an indispensable tool for the production of microelectronic devices where high precision and performance is required. Laserod has provided laser trimming systems and services to scores of customers for nearly forty years.

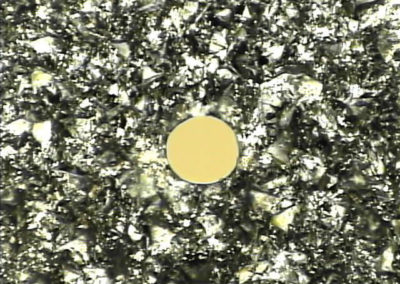

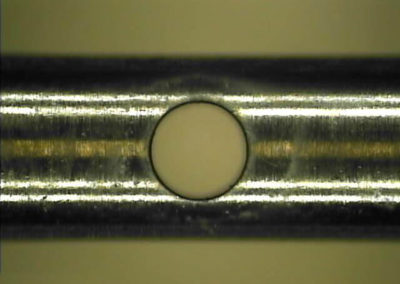

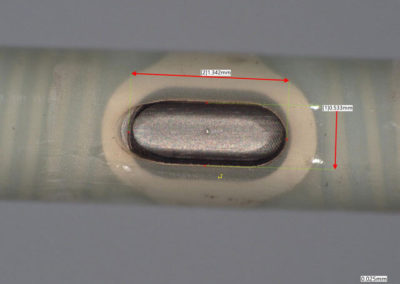

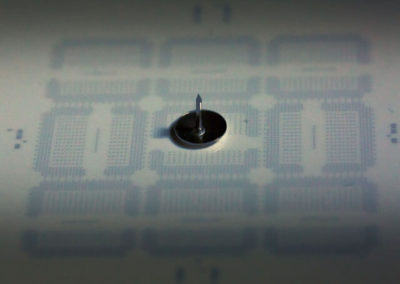

Simply described, the laser trimming process modifies the value of a resistor by laser removing resistor film material in a specific manner at a specific location. Resistance value of a film resistor is determined by its geometric dimensions. A lateral laser cut in the resistor narrows or lengthens the current flow path and increases the resistance value.

Passive Trimming is the adjustment of a resistor to a given value to increase its resistance. During the trimming process, the resistance or capacitance is monitored across the component until the target value is reached.

Active Trimming is the removal of material from a component to change a circuit parameter while the circuit is functioning. Parameters monitored are voltage, current, period, frequency.

LASER PARAMETER CONSIDERATIONS

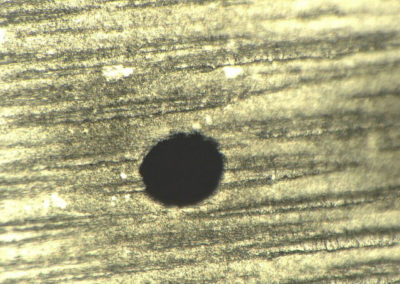

Spot Size – Laserod’s solid state laser spot size typically ranges from 10 to 75 microns. The spot size should be wide enough to avoid electrical arcing across a narrow trim as well as to allow for easier inspection of the bottom of the trim. However, the spot should be narrow enough that the laser power can be kept to a minimum, which reduces excess heat and avoids degrading the resistor’s long term stability.

Laser Beam Focus – For thick film trimming applications, the laser beam focus is a less important factor because the optics have very long depths of focus, typically +/- 250 microns. For thin film trimming, focus becomes a more critical factor, since resistor drift will increase as the beam goes out of focus in the near and far fields.

The Laserod LPS-T laser system is used for thick film resistor trimming, thin film resistor trimming, capacitor trimming, active trimming, semiconductor processing and micro-machining applications. The flexible design of the LPS-T allows it to be configured for a wide variety of applications in the hybrid microelectronics and semiconductor industries.

Laser Types

Femtosecond

1064nm/532nm/355nm wavelengths

Picosecond

1064nm/532nm/355nm wavelengths

Nanosecond

1064nm/532nm/355nm/266nm wavelengths

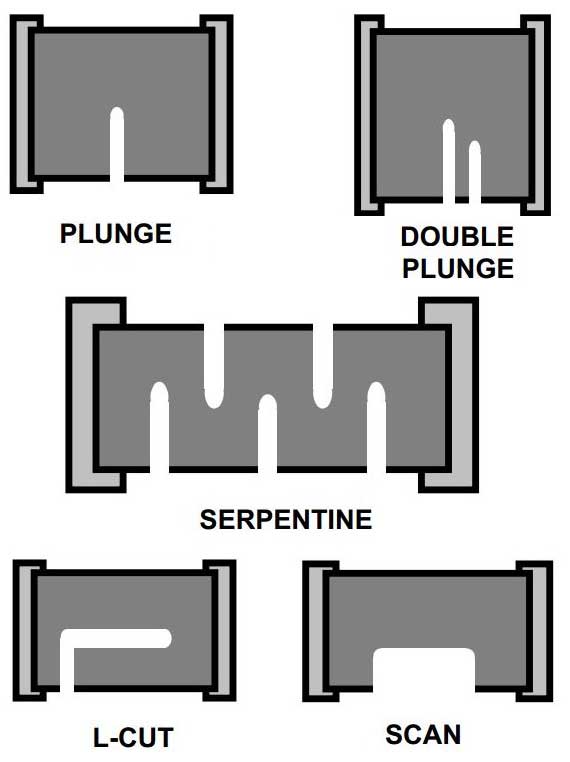

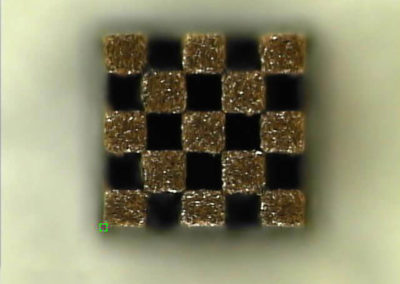

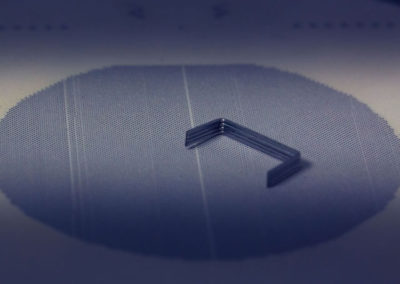

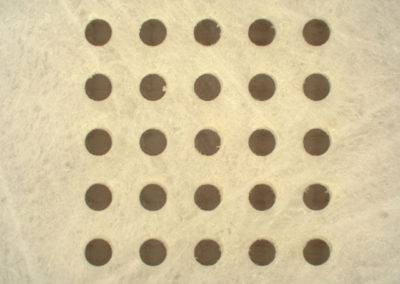

Types of Trims

(thick or thin film)

L Trim

J Trim

Plunge Trim

Serpentine Trim

Specs

Substrate Size: Up to 700mm x 700mm

Trim Tolerance: +/- 1%

Kerf Width: Down to 10ums

Feature Registration: +/-5ums