Wafer Laser Coring, Dicing and Resizing

Overview

Laserod has provided laser wafer coring and resizing services to scores of demanding clients over nearly a generation with precision that can’t be matched with conventional dicing methods.

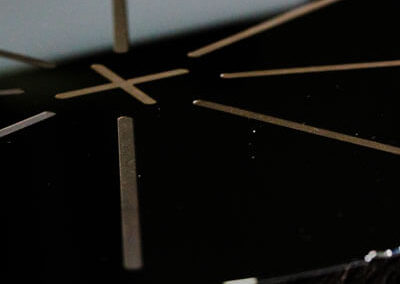

For over thirty years, Laserod has specialized in the coring (resizing), dicing and scribing of silicon wafers for the electronics and other industries. Laser wafer resizing is a more flexible and often less damaging alternative to the conventional mechanical sawing method. Laserod also machines silicon sensors, solar cells, MEMs and other photovoltaic devices by laser dicing or by a two-step scribe-and-break process that converts wafers into “dies” (aka “chips”).

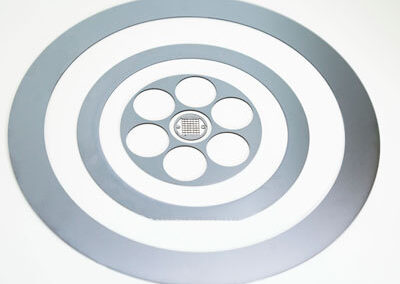

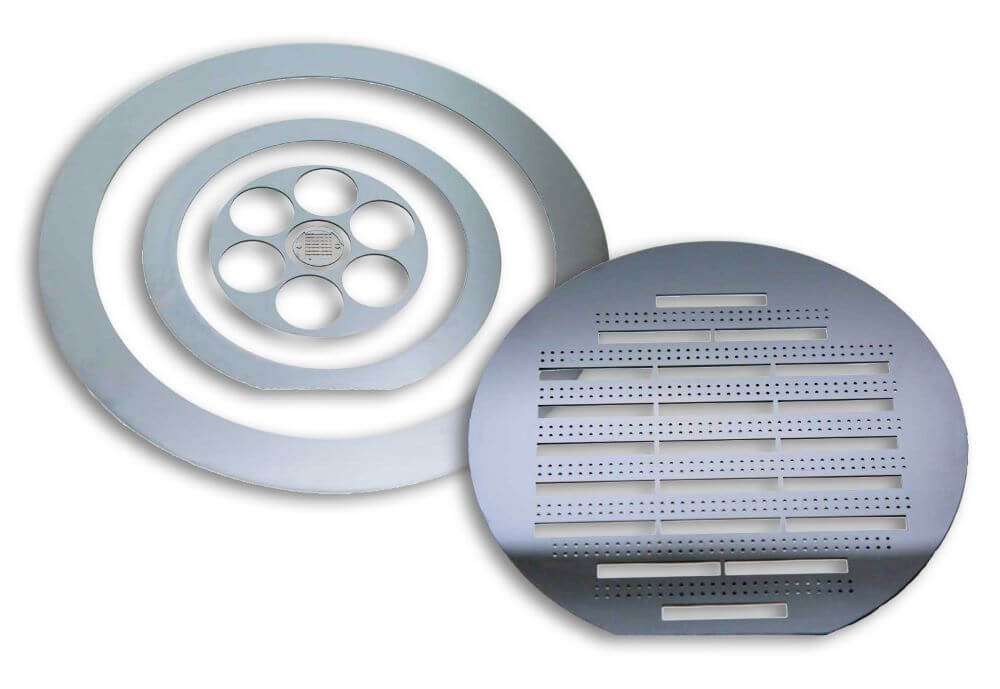

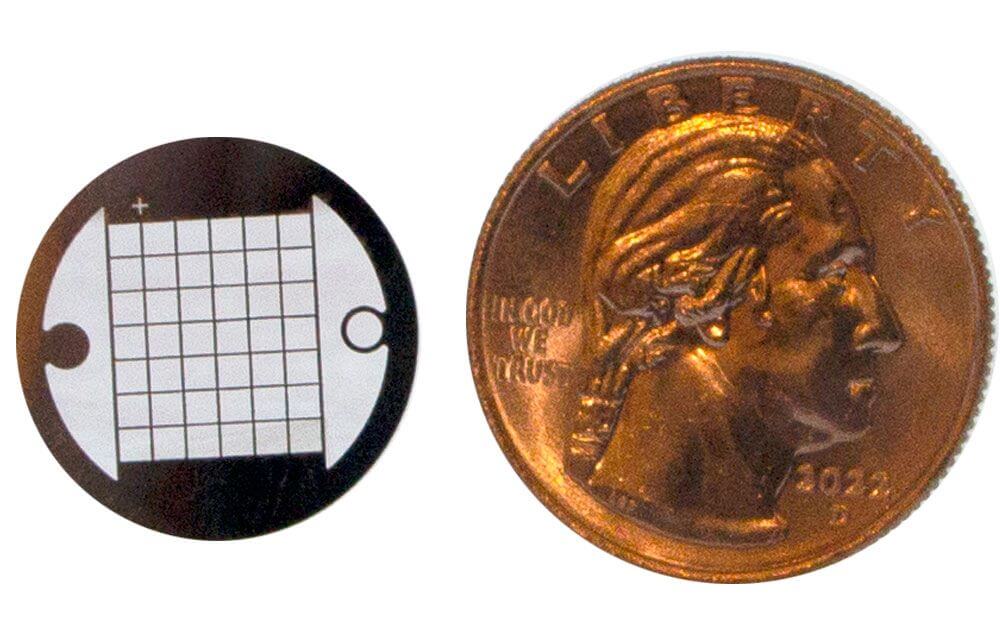

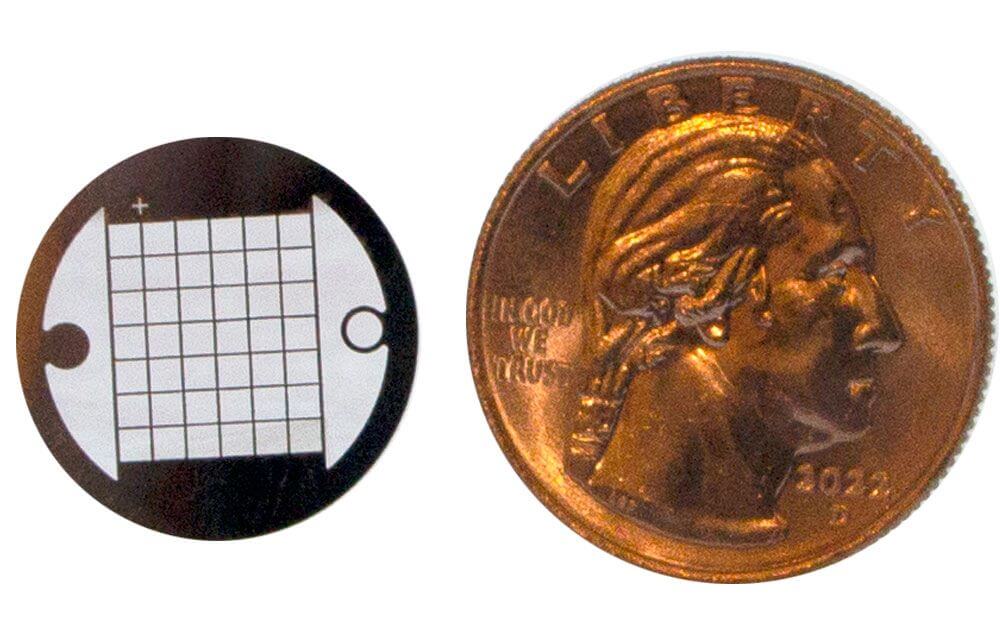

Commonly performed coring jobs are resizing 12″ to 8″ , 8″ to 6″; 6″ to 4″; or 12″, 8″, 6″ or 4″ down to multiple two inch wafers. Practically any kind of downsizing (coring) by laser cutting is possible.

A major advantage of laser wafer dicing over mechanical dicing is the flexibility to create curves, circles and geometries other than a simple array of rectangles. Laser dicing can cut a mixture of various sizes and shapes across a single wafer. The two-step laser scribing process also provides the ability to produce individual dies with minimal debris and low thermal impact.

Laserod’s wafer resizing standard services include:

- Typically silicon, though other materials are acceptable (silicon Carbide, Glass, etc.)

- Resizing/coring from 400mm max diameter to any smaller size and any wafer thickness up to 2mm

- Cutting of flats or notches with tolerances of +/- 0.025mm

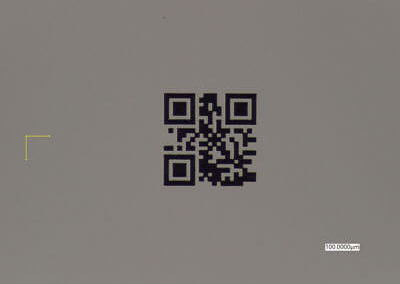

- Grinding, typically a rounded or beveled edge

- Video registration through a laser focusing lens, enabling Laserod to register/align to circuitry, fiducial marks or streets and avenues. Registration allows the resized wafer to be precisely aligned to features on the existing wafer, which in turn allows laser cuts to follow the streets and avenues.

Laser Types

Femtosecond

1064nm/532nm/355nm wavelengths

Picosecond

1064nm/532nm/355nm wavelengths

Nanosecond

1064nm/532nm/355nm/266nm wavelengths

Materials

Silicon (Si)

Sipcon Carbide (SiC)

Glass

Sapphire

Ceramic

Bonded Wafers

**Plus many others**

Specs

Wafer Size: Up to 700mm x 700mm

Wafer Thickness: Up to 3mm

Kerf Width: Down to 10ums

Feature Registration: +/-5ums

Notch/Flat Alignment: +/- .1 degrees