Femtosecond Laser Cutting

Overview

Femto lasers operate by emitting incredibly short bursts of light. These ultra-short pulses are intense but fleeting, which means they interact with material differently than longer laser pulses. This allows for a unique interaction with the target material, minimizing thermal effects and preventing heat damage.

When these lasers emit pulses, they can target specific areas of a material with incredible accuracy. This capability is essential for tasks requiring minute detailing or working with sensitive materials that can’t withstand high heat.

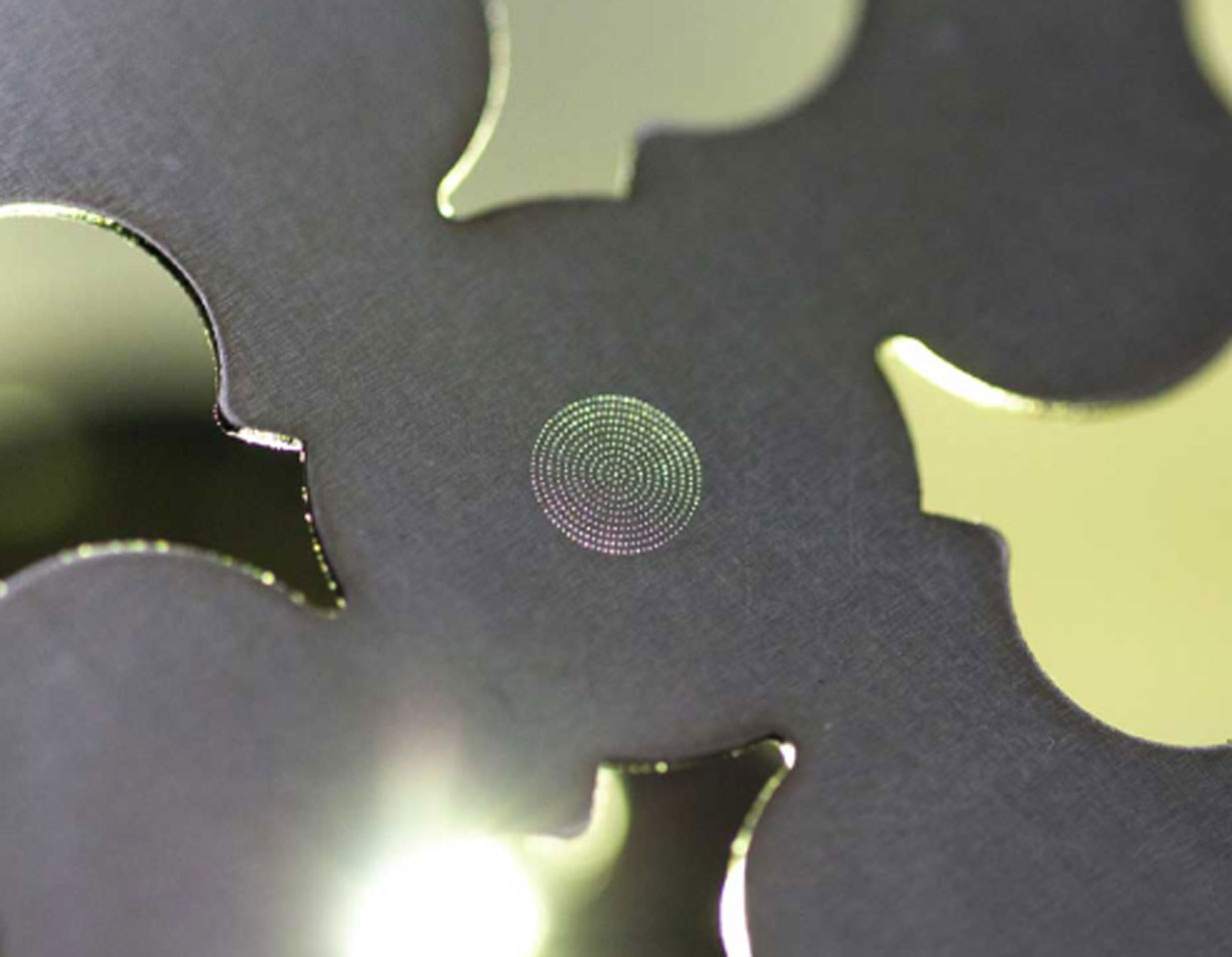

The end result is a cutting and engraving capability that is both extraordinarily precise and gentle on the material. Femto lasers can create intricate patterns, make ultra-fine cuts, and perform detailed engraving that would be impossible or impractical with traditional laser technology.

With Laserod’s state-of-the-art technology and laser cutting equipment, we can oversee our laser process with a full 3-D visualization, making our process fast, smooth, and efficient. For example, when laser cutting a cogwheel for a watch manufacturing client, it only takes Laserod about 30 seconds to complete the precision cutting. Precision is the key to such small and intricate components, where the functionality of the product depends on it.

With Laserod’s Femto laser cutting services, we can achieve ultra-precision cuts on even the smallest of parts, and we can do so in bulk, fast! Laserod’s Femto laser cutting is intended to provide 100% accurate micromachining, cutting, carving, and engraving for the tiniest, most delicate, most intricate components on the planet! For example, a cogwheel for a watch is just 1/8 of the size of a US dime! Of course, this is just an example of micromachining for a watch manufacturer. Our lasers can be used for photovoltaic cell scribing, glass cutting, or any other kind of micromachining. The Femto laser enables Laserod to engrave any material.

Laser Types

Femtosecond

1064nm/532nm/355nm wavelengths

Picosecond

1064nm/532nm/355nm wavelengths

Nanosecond

1064nm/532nm/355nm/266nm wavelengths

Materials

Silicon (Si)

Sipcon Carbide (SiC)

Glass

Sapphire

Ceramic

Bonded Wafers

**Plus many others**

Specs

Wafer Size: Up to 700mm x 700mm

Wafer Thickness: Up to 3mm

Kerf Width: Down to 10ums

Feature Registration: +/-5ums

Notch/Flat Alignment: +/- .1 degrees