Our precision-focused laser scribing technology is designed to meet the exacting standards required by applications in microelectronics, medical devices, and solar panels, to name a few.

Precision laser scribing, an essential process in these domains, involves accurately etching materials at the micron level.

With Laserod’s state-of-the-art laser scribe technology, clients can achieve the highest level of precision and efficiency, ensuring their products exceed industry expectations.

What Is Laser Scribing?

It is commonly used in the production of electronic devices, semiconductors, solar panels, and more.

A laser scribe machine uses laser pulses to create a narrow, well-defined line on the material’s surface, allowing for precise and consistent cuts.

In the laser scribing process, there are three laser types:

- Femtosecond (1064nm/532nm/355nm wavelengths) Femtosecond laser energy is best used for materials like glass and ceramics, which require ultrafast laser wavelength pulses.

- Picosecond: (1064nm/532nm/355nm wavelengths) Picosecond laser beam technology is ideal for precisely etching semiconductor materials such as silicon and gallium arsenide.

- Nanosecond: (1064nm/532nm/355nm wavelengths) Nanosecond pulsed laser beams are suitable for high-speed processing of metals and polymers.

At Laserod, we specialize in all three types of laser scribing machines to cater to the diverse needs of our clients.

We also accept custom laser cutting and scribing requests to provide solutions tailored to your specific requirements.

Understanding Key Parameters in Laser Scribing

In laser scribing, several key parameters dictate the process’s quality, efficiency, and precision. Here’s a brief overview:

- Laser Wavelength: The choice of laser wavelength is crucial as it determines the interaction between the laser and the material. Different materials absorb different wavelengths more efficiently. The right wavelength must be chosen for each specific material to ensure optimal absorption and minimal damage.

- Laser Power and Energy: Laser power is the rate at which the laser delivers energy, while laser energy refers to the total energy delivered per pulse. These two parameters significantly influence the speed and effectiveness of the scribing process.

- Laser Fluence: The laser energy deposited per unit area plays a pivotal role in achieving the desired ablation depth. Higher laser fluence usually leads to deeper ablation.

- Laser Ablation and Ablation Depth: Laser ablation is when the laser beam removes material from the surface to create a groove or cut. The extent to which the material is removed or the depth of the groove/cut made is known as the ablation depth. This is a critical parameter, mainly when working with thin films.

At Laserod Technologies, we understand the intricate balance between these parameters.

Our state-of-the-art laser scribing machines are equipped with advanced control systems that allow precise tweaking of these parameters to achieve the desired results, ensuring high-quality, consistent, and efficient laser scribing solutions.

Laserod’s Laser Scribing Services

- Aerospace and defense

- Automotive

- Biotech and medicine

- Semiconductor lasers

- Solar technology

- Telecommunications

- Touch display panels and electronics

- Research and development

- Amorphous silicon

- Glass

- Ceramics

- Metals

- Polymers

- Aluminum

- Diamond

- Kapton

- Carbon Fiber

- Composites

Our laser scribing solutions are known for their exceptional precision and customization. Moreover, our team of experts can also work with you to develop a custom laser scribe pattern that meets your product’s needs.

Whether you need thin film scribing, dicing, or cutting, Laserod has the expertise and equipment to deliver precise and efficient solutions for your laser scribing needs.

Benefits of Laser Scribing

- Precision: Laser scribing offers unmatched precision and accuracy, ensuring consistent results with minimal room for error.

- Versatility: With our advanced technology, we can work with a wide range of materials and create intricate designs and patterns regardless of their complexity.

- Speed: Laser scribing is a quick and efficient process, significantly reducing production time compared to traditional methods.

- Minimal Material Damage: The intense laser beam used in the scribing process minimizes material damage and eliminates the need for post-processing steps like polishing or grinding.

- Cost-effective: With faster processing times, minimal material waste, and precision control, laser scribing is a cost-effective solution for high-volume production.

Additionally, our state-of-the-art laser scribe machine can achieve these benefits without compromising on flexibility or customization.

Laserod’s Laser Scribing Process & Technology

Our laser scribing machines have advanced features such as a precision linear stage, precise beam steering systems, and automated vision systems for accurate positioning and alignment.

To give you an overview of our laser scribing process, here are the steps we follow:

- Client Consultation: Our team of experts works closely with clients to understand their requirements and develop a suitable solution. This also involves the production of a prototype for approval.

- Material Preparation: We begin by cleaning and preparing the material for scribing. This involves removing any debris or contaminants from the surface.

- Laser Setup: We adjust the laser parameters, such as pulse duration, spot size, and repetition rate, based on the material and desired outcome. We also prepare the scribe pattern using our advanced software.

- Laser Scribing: A laser beam is generated and focused onto the material surface using our state-of-the-art laser scribing machine. The laser scribes the material according to the predetermined pattern. The scribing process involves directing the laser beam along the scribe line, which removes material to create a precise groove or cut.

- Fine-tuning: Advanced monitoring systems in our laser scribing machine ensure the accuracy of the process, making real-time adjustments as needed.

- Quality Check: We perform a thorough quality check to ensure the final product meets your specifications and industry standards. The scribed material is inspected for any potential discrepancies or defects, ensuring the highest quality standards.

- Packaging and Delivery: The scribed material is carefully packaged and delivered to the client once the quality check is complete.

We also follow strict process parameters to maintain consistency and quality across all our laser scribing services.

Our laser processing facility is ISO 9001:2015 certified, ensuring we adhere to the highest quality standards.

We are also certified by the International Traffic in Arms Regulations (ITAR) to cater to the aerospace and defense industry, which means our facilities and technology meet these industries’ stringent security and quality requirements.

Hear What Our Clients Have to Say About Us

With an ISO 9001 certification and a registration at the ITAR, our clients can trust us to deliver precise and reliable laser scribing solutions.

We strive for excellence in every aspect of our business, from the initial consultation to the final product delivery.

Partner with Laserod for Your Laser Scribing Needs

Our advanced technology, expertise, and commitment to customer satisfaction make us the ideal partner for all your laser scribing needs.

Aside from laser scribing, we also cater to a variety of laser machining services, including but not limited to:

Wafer resizing and coring

Laser thin film etching

Laser resistor trimming

Laser hole drilling

Custom laser scribing and cutting

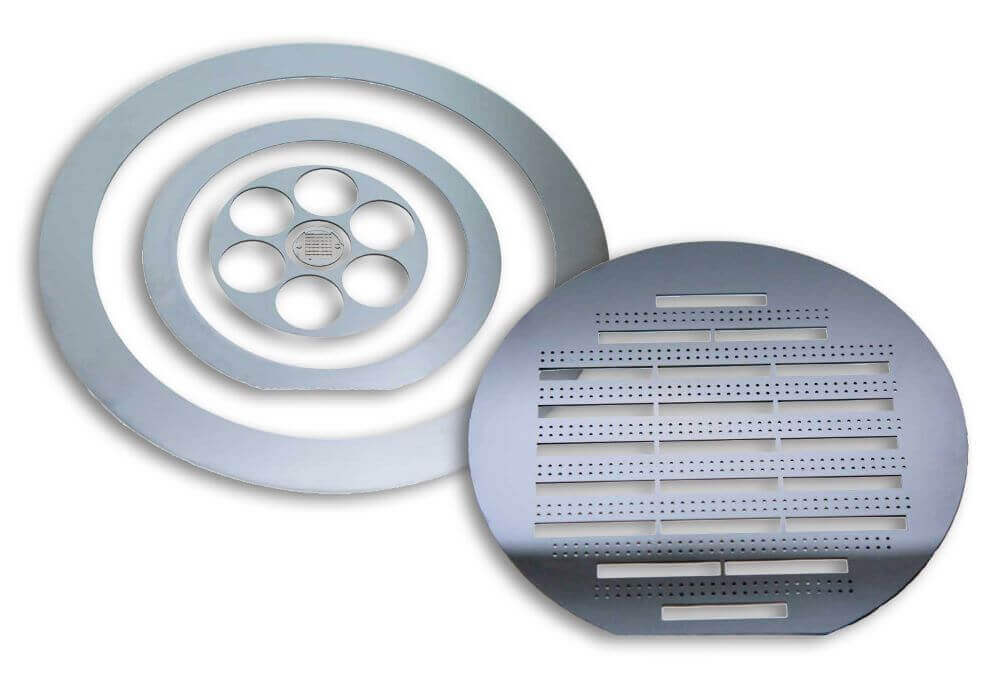

Some examples of our custom laser scribing and cutting projects include but are not limited to the following:

- Flexible PCB micromachining

- Direct laser patterning of transparent conductive coatings

- Direct Laser Patterning of touch panel displays

Contact us today at 310-328-5869 or by sending an inquiry to sales@laserod.com. Let us help you achieve your project goals with our laser scribing expertise.

FAQs – Your Laser Scribing Services Questions Answered

How fast is Laserod's laser scribing service?

Can Laserod's laser scribing services be customized for my specific needs?

What materials can be used with laser scribing?

What substrate specifications can your laser scribing process accommodate?

Will laser scribing damage my materials?

Additionally, with technologies like our nanosecond pulsed laser, the heat-affected zone is minimal, reducing potential damage to heat-sensitive materials.

How much are your laser scribing services?

Contact us today for a personalized quote based on your specific project needs.

Get the Finest Laser Scribing Quality with Laserod

That is why we continuously invest in cutting-edge technology, highly skilled personnel, and an unwavering commitment to customer satisfaction.

With our advanced laser scribing machines and expertise, you can expect exceptional results that meet or exceed your expectations every time.

Choose Laserod for all your laser scribing needs and experience top-notch solutions that are unmatched in quality, precision, and speed.

Contact us today and take the first step towards achieving your project goals with our trusted laser scribing services.