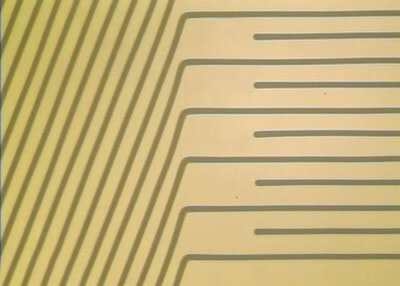

Laser Micro Machining

For over a generation, Laserod and its predecessor companies have provided laser micromachining products and services to many of the largest industrial corporations and most prestigious universities in the world. We assist companies in a broad variety of industries with their low-to-high production needs.

Laser micromachining is playing a crucial role in the manufacture of today’s electronic components as technology shrinks devices in size for improved performance and higher efficiency. Whether it be computers, medical devices, phones or automotive components, the demand for ever smaller parts increases every year by double digits.

Simply put, micromachining is the removal of small amounts of material by something other than a sharp edge tool. With lasers of the full range of wave lengths and rep rates, Laserod can machine materials as thick as 3mm and create features as small as 5-50 microns on nearly any thin material such as silicon wafers, plastic tubes, glass, metals, or ceramic. Among the numerous advantages of laser micromachining are minimal heat affect, closer tolerances, rapid cycle times, virtually no tooling cost, and high surface finish and edge quality.

Laserod is highly regarded for taking on demanding jobs for cutting-edge clients, including some of the world’s most highly regarded universities, aerospace companies, and medical instrument manufacturers. For higher volume clients, we take pride in our many decades of building both standard and custom laser systems. So, from concept through to volume production, Laserod has the facilities, experience, and flexibility to meet all of your laser micromachining needs.

Materials

- Stainless Steel

- Aluminum

- Glass

- Sapphire

- Ceramic

- Plastics

- Silicon

- Diamond

- Kapton

- Copper

- Carbon Fiber

- Composites

**Plus many others**

Specs

Substrate Size: Up to 700mm x 700mm

Substrate Thickness: Up to 3mm

Hole Diameter: Down to 5ums

Feature Registration: +/-5ums